Photovoltaic wire

| 1. Strong Weather Resistance: Required to withstand outdoor sunlight, rain, and sudden temperature fluctuations. These cables can operate in wide ranging temperatures, offering excellent resistance to UV aging, preventing cracking of the insulation layer caused by prolonged exposure. 2. Chemical Resistance: These cables withstand outdoor erosion, including acid rain, dust, and ozone, ensuring they are corrosion-resistant in complex chemical environments and maintaining stable electrical performance. 3. High Voltage Withstand and Insulation Reliability: Some cables also include an additional shielding layer to reduce the impact of electromagnetic interference on precision equipment such as inverters. 4. Mechanical Strength and Fatigue Resistance: Multi-stranded copper (or tinned copper) is often used as the conductor to enhance its resistance to stretching and bending, preventing breakage caused by long-term vibration (such as slight swaying of modules caused by wind). 5. Environmental Protection and Flame Retardancy: The system complies with RoHS and other environmental standards, and the insulation layer is made of flame-retardant material. Even if a short circuit fire occurs, it will quickly self-extinguish, reducing the risk of fire spread and meeting the safety requirements of photovoltaic power plants. |

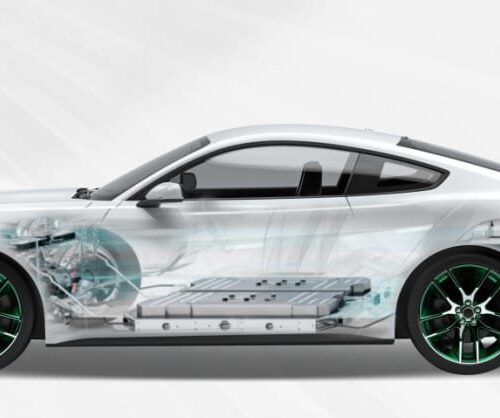

Photovoltaic wire mainly refers to enameled wire used in photovoltaic electrical components such as photovoltaic inverters, charging piles, and transformers. It is mainly flat wire and includes two varieties: EIWH and AIW. The maximum width can reach 16mm.

You must be logged in to post a review.

Reviews

There are no reviews yet.